With the high pressure demands of modern manufacturing there comes an almost endless amount of conveyor configurations available on the market today. Many factors contribute to correct conveyor selection for different products along with temperature sources, heating, cooling etc. Some factors include, life span, belt selection, which drive is going to be suitable, which controller? Is a generic off the shelf conveyor going to be suitable to your application and work in with your associated equipment? Do you require a mechanically designed purpose conveyor fabricated to suit your requirements? The conveyor options and configurations are endless!

With the high pressure demands of modern manufacturing there comes an almost endless amount of conveyor configurations available on the market today. Many factors contribute to correct conveyor selection for different products along with temperature sources, heating, cooling etc. Some factors include, life span, belt selection, which drive is going to be suitable, which controller? Is a generic off the shelf conveyor going to be suitable to your application and work in with your associated equipment? Do you require a mechanically designed purpose conveyor fabricated to suit your requirements? The conveyor options and configurations are endless!

We find that many of our clients ask the following questions; Can we modify an existing conveyor, or do we need a new system?

Some of the considerations when weighing up your decision on new design versus modifications to existing.

Is the existing conveyor suitable for new/existing purpose?

Does the conveyor provide you the volume output of production?

Belt suitability for your application? Modular belt or PU Belt?

Will the drive or belt need to be replaced?

Does existing conveyor meet current hygiene and Australian Safety Standards?

We can provide a skilled trades person to visit your production/manufacturing site and conduct a conveyor audit to ensure its meeting the necessary Australian Safety requirements along with performance output requirements? By establishing this we can assist with modifications or design and manufacture a new conveyor system based around those findings.

Whether you have new products or change of line equipment we can assist with conceptual design, mechanical drawings and when suited 3D drawings to provide complete line overview.

Below is a list of conveyors Jarlam provides along with the industry and uses:

Wire Mesh Belt Conveyors:

Confectionery and Bakery, primarily products that are coated (Chocolate, sprinkles, coconut flakes). Mesh belt conveyors allows the product to be enrobed by the coating, allowing excess to fall through and then be reused to save on product wastage.

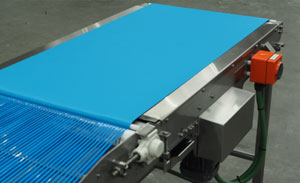

Plastic Modular Belt:

Modular belt conveyors are a versatile conveyor widely used in the Pharmaceutical, Meat Processing, Industrial Bakeries, Snack & Confectionery. Modular style conveyors can be utilised in most production line areas, from processing to packaging.

Multi-Directional Conveyors:

Multi-Directional/Conveyors have rollers that extend above or below the belt surface. These rollers/wheels are positioned at an angle in relation to the direction the belt travels. They are used within the packaging process lines.

Flighted/Incline Conveyors:

Incline conveyors are through all industries. Bakery, confectionery, food, Beverage, pharmaceutical and packaging. Incline conveyors are used to move food/pharmaceutical products between elevations.

Spiral & Vertical Conveyors:

Industries utilize Spiral conveyors to accumulate/stage /cool products within a confined space. Spirals are heavily used with-in the food and confectionery industries.

There are many conveyor configurations for all types of applications, give the team at Jarlam a call today to discuss the best options for your applications 03 9762 6833.