In recent years, companies have invested heavily to support Computer Aided Design (CAD) design, production management, and scheduling to streamline workflows. Jarlam Australia is at the forefront of CAD technologies, from 2D factory layouts to 3D mechanical design. From simple components to completed assemblies of plant and pieces of equipment.

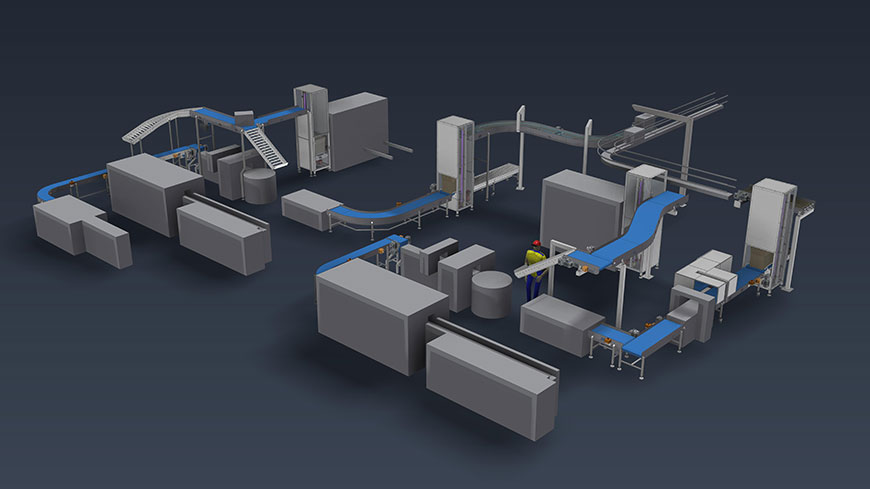

This benefit of virtual designs helps our customer visualise their final layouts of the factory floor, or for the final approved design of purchased equipment. By providing intelligent design and automated workflows to our customers, Jarlam Australia are able to improve the efficiency of the process, eliminating errors from hand sketches, to improving speed of deliver to site, on time and in full.

Jarlam Australia’s mechanical designers utilise Autocad Inventor to work in conjunction with our fabricators and mechanical technicians. This ensures efficiency in both the design layouts and manufacturing processes.

With our inhouse engineers and fabricators working within the team, this ensures full alignment where the mechanical designer does not need to redesign the part for fabrication. Excellent internal communication between the design office and shop floor is crucial, as it ensures we get the most out of both sides of the manufacturing process. It also saves our clients valuable time and money.

3D Layout

Jarlam Australia has the capability to assist you with both mechanical design and fabrication processes by utilising Autodesk, AutoCAD, and Autodesk Inventor software.

We store all our components in AutoDesk Vault, which allows us to access the files remotely, meaning that our engineers and technicians can access and modify the drawing from anywhere, with access to the internet.

Another benefit of utilising AutoDesk Vault, our designer can avoid redrawing the same parts repeatedly. We can build libraries of parts for your project, allowing the design team to utilise parts from previous jobs, flawlessly on the new design.

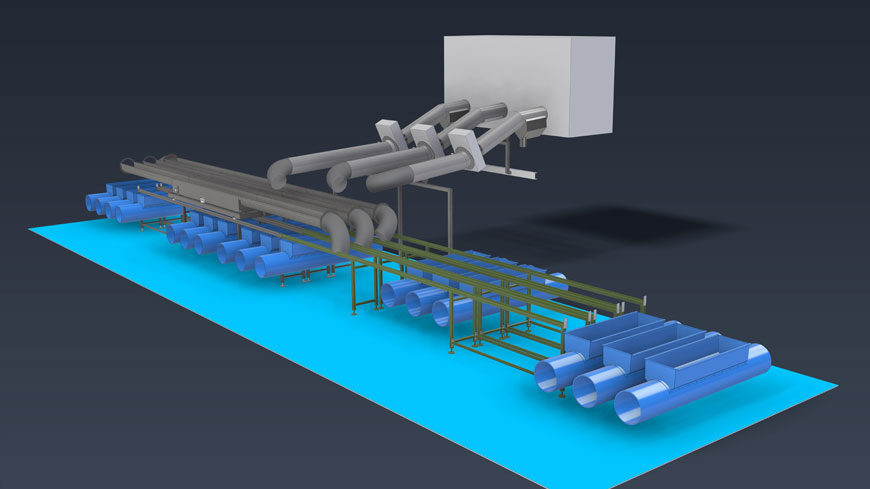

2D Layout

All factory improvement projects start with reviewing current and existing layouts. This review ensures the accuracy and safe access to all equipment in a conceptual layout. Often there are many restrictions within processing plants (other equipment lines, refrigeration lines, heating or cooling lines, etc.) that all provide their own unique challenge to its layout. Through years of experience our design engineers works through the design systematically to ensure each item is meticulously placed for production and process flows. This design utilises as little footprint as possible while satisfying our customers’ requirements.

Our mechanical designers have been involved in continuous factory improvement layouts, as well as the design of mechanical equipment to include:

- Conveyors

- Platforms

- Walkways

- Passthroughs

- Trolleys, and more

With the experience and highly developed skills of our mechanical designers; with Jarlam Australia you can be ensured that we can supply a solution to your design needs.

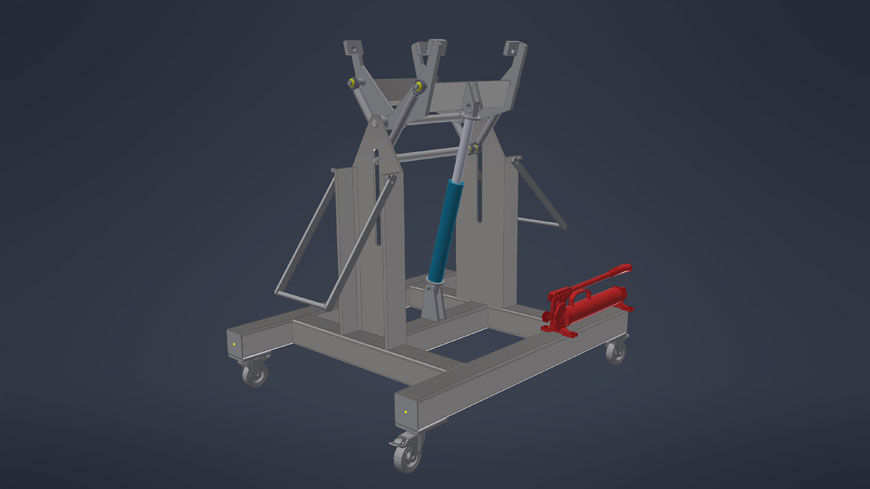

3D Model

Our design engineers and draftsman are also capable of designing components or equipment in 3D space. If no sketch or drawings for existing machinery are available, we can reverse engineer options based on our client’s requirements for any particular component or piece of equipment to develop a 3D model.

Majority of conceptual design is best presented in three-dimensional space, and Jarlam Australia are capable of supplying 3D drawing in a PDF format. Customers will be able to view the part or machine without the need or access to a CAD system.

Bill of Material (BOM)

We supply all our mechanical assembly drawings with accurate and detailed BOM. This will allow the ordering of the material necessary for swift, correct fabrication. The BOM may also serve as a spare parts and future procurement list for our valued customers.

Simulation

You should never separate engineering from testing of material, and to simulating how a mechanical system behaves in the real world. By simulating in the virtual world, we can complete the fabrication process, without the need to go through multiple revisions, to satisfy our customers’ requirements.

Process

To begin, the customer supplies us with rough sketch of the required design. Our engineers then supply a concept drawing shortly after (depending on the complexity of the design).

From here, our engineer will discuss the project with our customer to ensure that all requirements have been covered and that our customer is happy with the final design.

The last stage of the process will be the completion of the fabrication drawings/technical drawings so that we can fabricate the design on the shop floor.

Contact us today for further information on our CAD services.