At Jarlam, we are dedicated to providing an exceptional conveyor installation service tailored to the diverse needs of our clients. Our expertise spans across various conveyor systems, including conveyor belt installation, assembly and modifications to existing conveying systems. Utilizing precise conveyor installation techniques, we ensure each conveyor, and its components are accurately installed, guaranteeing minimal downtime and maximum efficiency. Jarlam is adept at handling all aspects of conveyor equipment, conveyor belt and service installation, from supply to final setup. By prioritizing safety, we strive to supply seamless conveyor solutions that enhance productivity and operational success in the many industries.

Why Expert Conveyor Installation Matters

Our team understand the importance of an expert conveyor installation service, ensuring efficiency and the longevity of your operations. Our professional approach to installing conveyor systems guarantees each conveyor line and its components are precisely installed, minimizing downtime and maximizing productivity. With Jarlam, you benefit from a comprehensive conveyor install service that covers every aspect of conveyor belt installation, from the supply of high-quality equipment to the meticulous setup of conveying systems.

Our inclusive and collaborative conveyor installation methods ensure that your specific conveyor installation needs are met, and our expertise translates into reliable and seamless conveyor systems. Choosing Jarlam for your conveyor installation means investing in a partner dedicated to enhancing performance, operation and efficiency of your production line.

Types of Conveyor Belt Systems

Jarlam specialize in the fabrication and installation of a diverse range of conveyor systems to meet the unique needs of various industries. Our expertise includes:

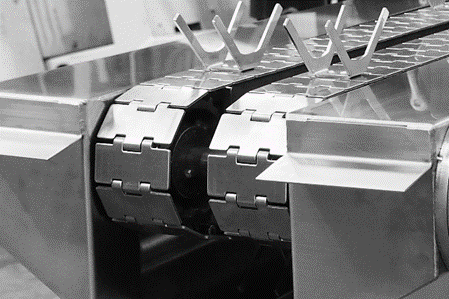

– Modular Conveyor Belt Conveyors: Ideal for versatile operation, speed and efficiency.

– Slat Chain Conveyors: Ideal for heavy-duty applications.

– Cord Conveyors: Perfect for delicate handling.

– Wire Mesh Conveyors: Provide excellent airflow and drainage.

– Spiral Conveyors: Save valuable floor space.

– Merge Conveyors: Ensure efficient product sorting.

– Indexing Conveyors: Enable precise product placement.

– Pack-off Conveyors: Streamline packaging processes.

– Reject Conveyors: Ensure quality control.

– Spreader Conveyors: Distribute products evenly.

– Alignment Merge Conveyors: Offer accurate end product alignment.

– Incline Conveyors: Facilitate the movement of products to different elevations.

And so much more.

Choosing the Right Conveyor for Your Business

So now that you know the types of conveyors available, choosing the right conveyor system for your business is essential to optimize productivity and efficiency. At Jarlam, we understand that each business has unique needs, and we are here to guide you in selecting the ideal conveyor system. Our comprehensive range of design, fabrication and chalk line installation services covers everything your business needs for a turnkey solution to the complex world of conveying systems.

By partnering with Jarlam, you benefit from our expertise in designing, fabricating and installing high-quality conveyor belts and components. Our team ensures that all components are expertly installed, resulting in minimal downtime and seamless operation. We pride ourselves on delivering tailored conveyor solutions that enhance your production line, ensuring your conveyors and systems are perfectly aligned to meet business goals. Trust Jarlam to supply reliable, speed efficient, and customised conveyor systems that drive your success.

Pre-Installation Planning for Conveyor Systems

Meticulous pre-installation planning is integral to ensuring a smooth conveyor installation service. Our engineering team’s schedule begins with comprehensive CAD design, meticulously crafted floor and conveyor layouts, and specifications tailored to each client’s needs.

Fabrication drawings further enhance precision, and detailing components help to streamline the conveyor installation process. By prioritizing detailed planning, from design through to conveyor installation, Jarlam Australia guarantees delivery of an efficient and reliable conveyor installation service that meets the highest standard of quality and performance.

Site Preparation and Safety Measures

Site preparation and safety measures are paramount in our approach to installing conveyors. Before any installation begins, our team takes the time to conduct a thorough assessment of the site to understand floor conditions, space constraints, and logistical requirements that may impact the conveyor installation.

Our project management team ensures a Job Safety Analysis is completed for each conveyor installation and is communicated to both our conveyor installation teams on site and others who may be involved in the project. This groundwork allows Jarlam to tailor an installation plan to suit the required needs of the conveyor installation, ensuring time efficient assembly, minimal risk and minimal downtime.

Safety is our top priority, and we adhere to strict protocols to protect both our conveyor installation teams and the site environment throughout the installation process.

Common Conveyor Installation Challenges

Jarlam tackle the complexities of conveyor installation head-on. Installing conveyor systems involves overcoming challenges, from coordinating equipment delivery, time restraints and navigating site constraints, to ensuring the seamless assembly and integration of components.

Our experienced conveyor installation teams understand the importance of minimizing downtime and optimizing system performance. Whether it’s hard to access install areas or commissioning and assembling a fully operational conveyor belt line, we pride ourselves on delivering conveyor solutions that meet our clients’ needs.

Our expertise ensures that every conveyor installation is completed on schedule, within budget, and with minimal disruption to our clients’ operations. You can count on Jarlam to navigate these challenges and deliver expert conveyor installation services that set your operations on the path to success.

Integrating Conveyors Belt Lines into Existing Systems

Ensuring Compliance with Industry Standards

Ensuring compliance with industry standards is a cornerstone of our conveyor installation services. We meticulously adhere to conveyor hygiene and safety regulations to meet stringent food and pharmaceutical industry requirements. Our conveyor installation team’s expertise in understanding and implementing these standards ensures that every component is installed with precision, minimising contamination risks and ensuring optimal performance.

We take pride in our ability to deliver installations that align with clients’ operational needs, from initial design and assembly to the final commissioning. By prioritising compliance, Jarlam guarantees conveyor installations that meet industry standards and enhance the efficiency and reliability of client production lines.

Electrical Assistance in the Installation of Conveying Systems

As an affiliate company to Jarlam Australia, Jarlam Electrics offers electrical service expertise in the commissioning, assembly and installation of conveyors.

https://www.jarlamelectrics.com.au/about-us/

Benefits of Professional Conveyor Belt Installation Services

Our conveyor installation services ensure that our clients receive the benefits of our extensive experience and expertise in conveyor installations. Our clients can be assured that their conveyors are installed to ensure precise alignment and tension, to ensure optimal efficiency and longevity.

Our conveyor installation teams also understand the nuances of different conveyor systems, handling complex installations efficiently and effectively, minimizing the risk of errors. By engaging professionals for your conveyor belt installation, you can be assured that all safety standards and regulations are met, reducing the risk of accidents or malfunctions.

Innovations in Conveyor Systems Installation Technology

Innovations in conveyor system installation technology remains at the forefront of our conveyor installation practices. Conveyor system installation technology continues to evolve day by day and our conveyor installation teams continue to review conveyor installation practices to improve efficiency, safety, and adaptability.

Why is Jarlam Australia a Leader in Conveyor Installations?

Our conveyor installation team is the backbone of our business. Each conveyor installation team member is fully qualified in their trade and has extensive experience in conveyor installations. Our team includes skilled fabricators, fitters, and other specialists, all dedicated to setting high standards and successful conveyor installations.

We take pride in offering our clients highly skilled and experienced professionals who are not only experts in conveyor installations but also great to work with. Our core values and behaviours include:

- Customer Service: We are personable and professional, treating everyone with respect.

- Reliability: We complete projects on time, on budget and meet deadlines.

- Pride: We maintain high standards for project completion.

- Teamwork: We prioritise safety and collaborate to achieve client and team goals.

- Communication: We are honest, trustworthy, and communicate respectfully to build long-lasting relationships.

Specialised Equipment to Assist with Conveyor Installations

Case Studies of Successful Installations

With close to 20 years of experience and service in the industry, and thousands more completed conveyor installation projects, Jarlam has established a reputation as a market leader in conveyor belt installations and commissioning.

View the links below to learn more about successful conveyor belt manufacturing and conveyor installation case studies!

https://www.jarlam.com.au/industry-projects/conveyor-manufacturer/

https://www.jarlam.com.au/industry-projects/equipment-installation/

Conclusion: Investing in Quality Conveyor Installation for Long-Term Gains

Investing in quality conveyor installation services is crucial for ensuring that your conveyor systems are correctly assembled in the most efficient manner. By choosing experienced professionals to complete this type of work, clients can expect:

- Timely Installation: Delivery of project on time.

- Expertise & Precision: Work is executed according to specifications

- Minimal Downtime: Reduces the likelihood of breakdowns & ongoing service & maintenance issues

- Low Maintenance Requirements: Quality installation leads to fewer service & maintenance issues

- Long Term Longevity: Expert installation contributes to durability and extended lifespan