Client Background

- Our client for this project is a leading food manufacturer in Australia and across the Asia Pacific.

- They are custodians of some of Australia’s and the Asia Pacific’s most recognised food brands.

Project Overview

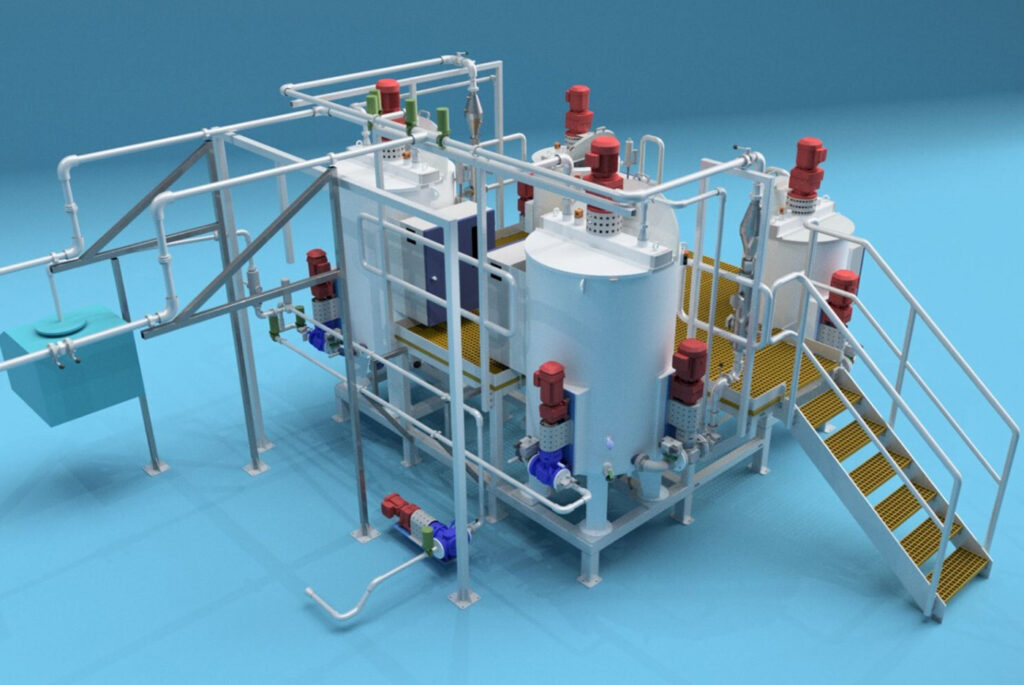

As part our engagement with the client our scope of works encompassed the design, fabrication, and delivery of a custom-made platform that had to be specifically designed to support large Agitator Tanks filled with product.

In addition to this our responsibilities also included the design, fabrication and installation of all jacketed pipework and control valves that would integrate the platform and tanks with the equipment responsible for the processing of product.

Solution

Without a full design brief, our Design Engineers were tasked with the responsibility of engaging with the client to develop the design brief for the platform and associated pipework.

As part of the design process for the custom-made platform, our Design Engineers had to consider equipment weight, the distribution of product, load capabilities and installation / delivery requirements. As part of the solution provided, our Design Engineers were able to design the platform in a way that evenly distributed weight to account for the load capabilities, hygiene and the distribution of product. In addition, the design team allowed for the provision of delivery and installation by designing the platform in such a way that it could be delivered / installed in sections.

As part of the pipework design brief our Design Engineers had to consider process flow, hygiene, contamination, and ease of access for both the maintenance and operations stakeholders. The final process pipework design ensured that all considerations were considered and that any chance of product build up or blockage was alleviated.

As part of our design capabilities our Design Engineers were able to generate a full 3D model based of the design brief, offering real-time visualisation of the proposed concept.

Our workshop team were then able to fully fabricate the platform and pipework to meet hygienic food standards, for our experienced site teams to then efficiently and effectively install everything.

Benefits / Outcome

By working collaboratively with our customer, we were able to provide a design concept that aligned with their requirements and objectives.

As a result of the design and fabrication, the final product and output improved efficiency, maximised functionality, ensured minimal down time and improved the overall production on the line.

100% Customer Satisfaction

On Budget

High Quality Workmanship