Client Background

- Our client for this project is a global producer of flour, ingredients and bakery products.

- Specialising in the supply of bakery products to major supermarkets across Australasia, we are proud of our longstanding collaboration with this client.

Project Overview

As part of this project our client required a design solution to replace existing outfeed/bypass conveyors with a new and improved version, that would eliminate product misalignment and interact with the existing production line.

Solution

As part of this project, our Design Engineers undertook a case study and completed the necessary research to gain an in depth understanding of the existing challenges our customer was facing.

As part of the engagement process it was identified that the current functionality of the existing production line was being hampered by numerous transfers, the type of belt and its radius.

Our Design Engineers were able to use their extensive experience in the food and manufacturing industry to identify the core issues at hand and develop a conveyor solution that:

- Reduced the number of transfers from four to two.

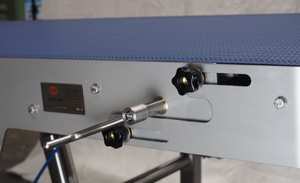

- Incorporated a tilt mechanism that resulted in a hybrid conveyor.

- Introduce a new custom belt design custom made to meet the exact specifications of the line.

- Was carefully designed to ensure the nose bar of the conveyor was concise and was easily incorporated into the existing production line for increased functionality/alignment.

Throughout this process our design team was able to utilise existing design software to ensure compatibility with the existing production line and real-life visibility for the end user for approval.

The suite of engineering drawings was then passed on to our expert fabricators and fitters to provide a high-quality manufacture of the ‘Tilting Conveyor’.

The final piece of the puzzle involved our onsite installation team installing and incorporating the solution into the existing production line with precise conveyor alignment.

Benefits / Outcome

We are extremely proud of the solution our Design Engineers were able come up with to eliminate some really challenging issues for our customer.

As a result of this solution our client has seen a significant reduction in product misalignment, an increase in production, increased productivity by the end user and an overall reduction in down time and maintenance.

Our easy clean design has also resulted in less down time for cleaning and the overall design and workmanship has a resulted in an uptake in the hygiene levels of the line.

Increase Productivity

Increased Cleanliness and Hygiene

High Quality Workmanship