Introduction To Spiral Conveyors: An Overview

Spiral conveyors offer cutting edge vertical conveying solutions that optimizes the use of valuable floor space and boosts production volumes.

Featuring advanced technology and forward-thinking design, spiral conveyors convey products in a vertical manner, ensuring a continuous flow and enabling high throughput.

The Importance of Spiral Conveyors in Modern Industries

Inflationary pressures and the cost-of-living crisis has heightened the need for industry leaders to streamline processes and lower food costs to consumers.

Spiral conveyors across the food industry are becoming increasingly popular as a way to achieve:

- Space Efficiency: Vertical conveying optimizes floor space.

- High Speed Food Processing & Packaging Operations: Spirals enhance product volume and throughput.

- Flexible Conveyor Systems: Spirals can be customized for various solutions.

- Improved Safety Features: Hygiene and safety features are integrated.

- Versatility: Spiral conveyors are a flexible conveyor capable of handling diverse products like trays, cartons and bulk material.

- Reduced Footprint: Unlike traditional conveyor systems that require extensive horizontal space, a spiral conveyor and its vertical design, makes them ideal for a small footprint or a facility where floor space is at a premium.

Design Considerations for Spiral Conveyors

Spiral conveyor design is a sophisticated blend of engineering and efficiency, aimed at optimizing vertical space, whilst achieving a smooth and continuous flow of product.

Floor space plays a crucial role in the design phase to ensure optimal operation and efficiency of the conveyor. To achieve vertical conveying and maximize space utilization, it’s essential to account for the widths and diameter of both the conveyor and belts to accommodate product size and weights. Additionally, selecting appropriate materials is vital to ensure hygiene, durability, low maintenance, and overall efficiency of the conveyor system.

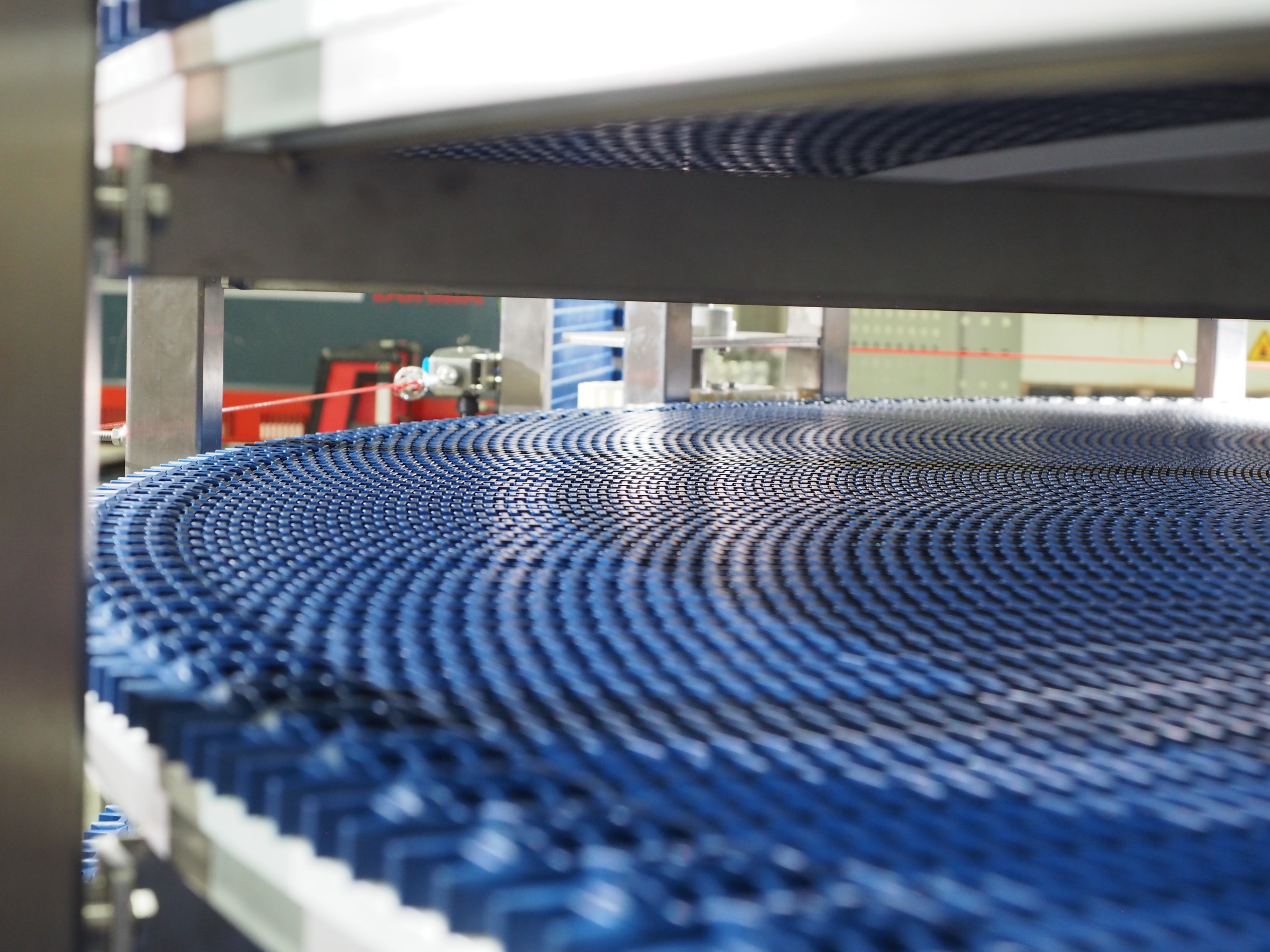

Selecting the right speed and belt is pivotal for optimizing the operational efficiency of the spiral conveyor. Consideration should include speed variables, loads and motor specifications to ensure a smooth and continuous flow of product throughout the spiral conveyor. Belt selection might also involve features such as a rolling friction belt or a low friction operation. Ultimately, the chosen belt must be compatible with the spiral conveyor design and the products being transferred to ensure efficient operation.

Advanced spiral conveyor design will often include many features, features which include, adjustable belt tension, bearings variation, automated controls and modular components. Overall the design of the spiral conveyor is crucial for achieving a low maintenance solution, conveyor durability, operational efficiency and a long life conveyor solution.

Choosing The Right Spiral Conveyor Manufacturer

Selecting the right manufacturer for your spiral conveyor is essential for ensuring operational efficiency and project feasibility. When choosing your spiral conveyor manufacturer, consider the following factors:

- Experience & Reputation: Choose manufacturers with proven experience in spiral conveyor design and fabrication. Positive reviews and a strong reputation can indicate reliability and expertise.

- Customization Capabilities: Ensure the spiral conveyor manufacturer deliver a suitable customized solution that meets your specific requirements, including materials, load capacities, speeds, two tracks, bearing options and flexible design.

- Technology and Innovation: Look for spiral conveyor manufacturers who embrace technology and innovative designs, which are key for energy efficient and low maintenance conveyors.

- Support & Service: Evaluate the level of customer service provided, including installation assistance and trouble shooting services.

- Cost & Value: Compare pricing to ensure your receive the best value. Be aware that the lowest cost option may not always offer the most efficient or low maintenance solution.

- Lead Time & Delivery: Confirm the spiral conveyor manufacturer can meet your project timelines and deliver the conveyor within the required timeframe.

Exploring Jarlam’s Cutting-Edge Spiral Conveyor Solutions & Design Excellence

Jarlam Australia specializes in the design of spiral conveyors, providing a bespoke conveyor solution to suit small footprint operations to ensure valuable floor space is optimized.

Jarlam offers spiral conveyor solutions across every market, including the food industry. We strive for excellence in spiral design and provide comprehensive services including design, fabrication and installation.

Our skilled engineers specialize in spiral design, creating bespoke spiral conveyor solutions from inception to completion and supporting spiral refurbishments. Supported by our in house fabrication workshop, our teams work together seamlessly to deliver customized spiral conveyor solutions, designed and manufactured under the one roof.

Jarlam installation teams are equipped to transport and install your spiral conveyor efficiently. We provide all necessary equipment, special tools, and materials to ensure a swift and precise installation of your spiral conveyor, optimizing operational efficiency and product performance.

With the combined expertise of our entire team, clients can be assured that their spiral conveyor will be designed using the most suitable material and carefully assembled to operate to the highest of standards.

Case Studies: Successful Spiral Conveyor Implementations

Jarlam Australia has extensive experience in spiral conveyor design, fabrication and installation. Click on the below link to view conveyor design, fabrication and installation case studies.

https://www.jarlam.com.au/industry-projects/conveyor-manufacturer/

Visual Guide: Stunning Spiral Conveyor Designs

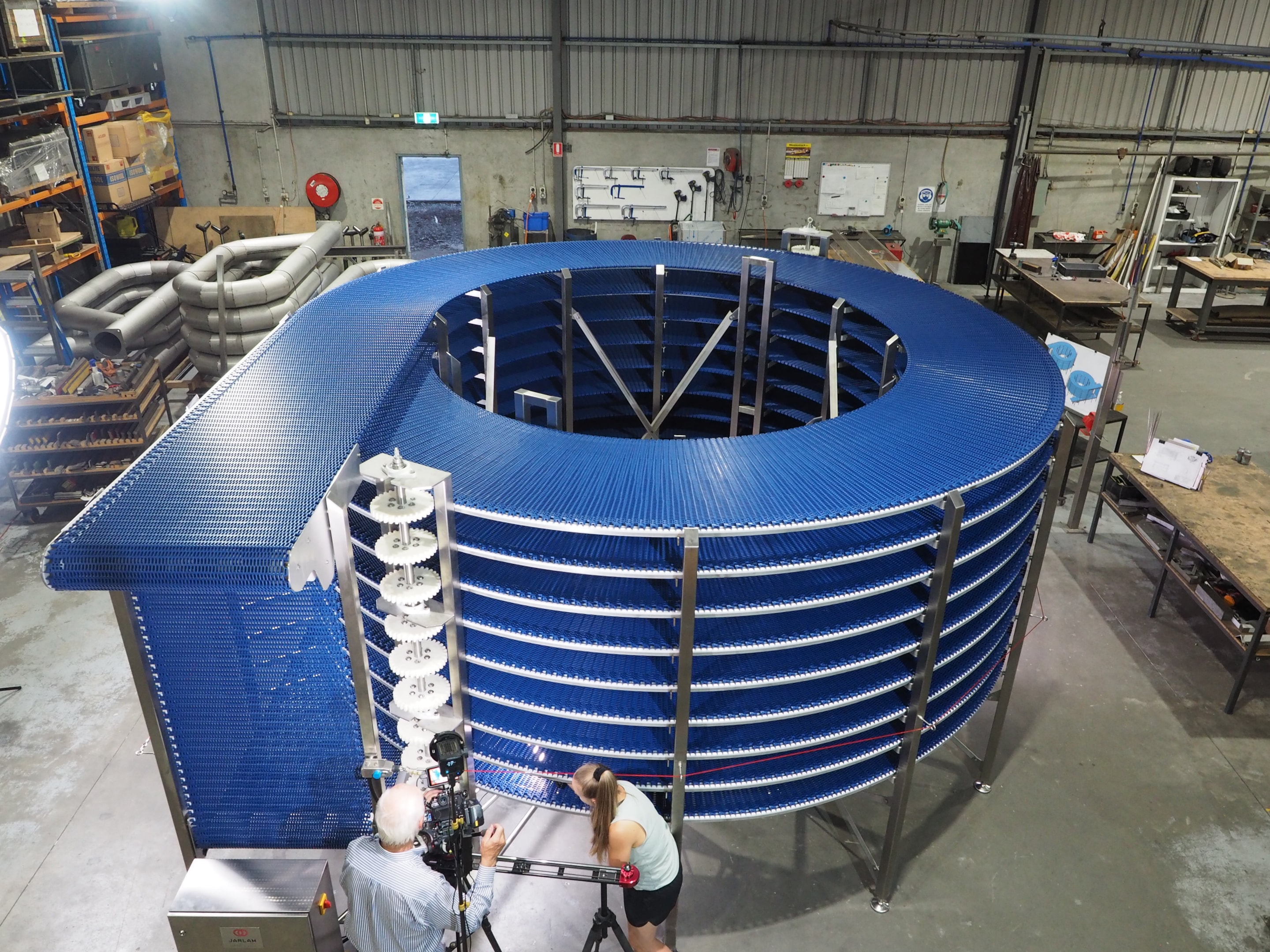

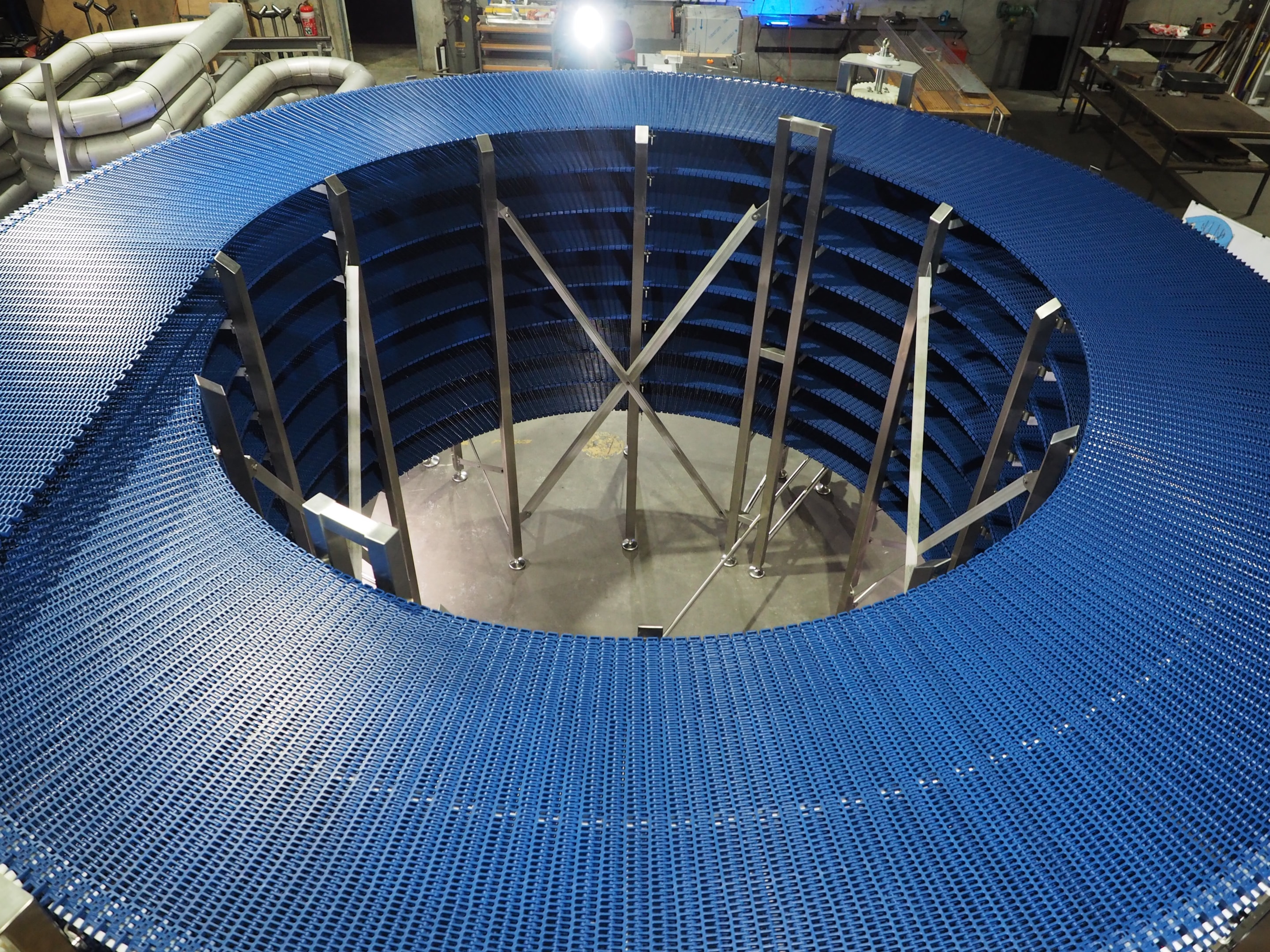

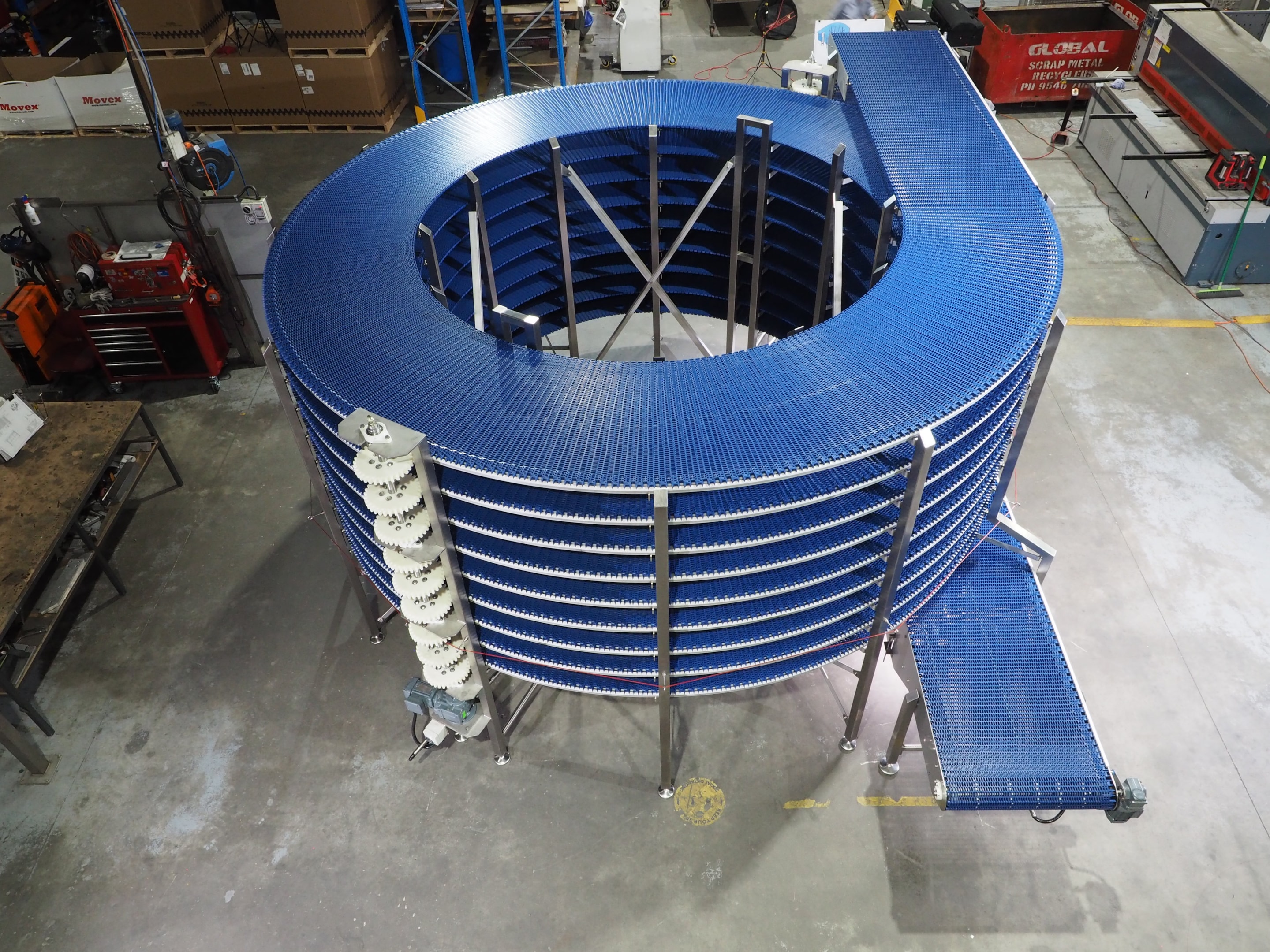

As industry leaders, Jarlam Australia proudly designed and manufactured the first ever side drive spiral conveyor in the Southern Hemisphere. This bespoke conveyor, was designed using high quality material with a focus on space optimization and speed variation to ensure flexibility and optimal product efficiency.

The images below showcase Jarlam Australia’s expertise in both design and fabrication.

For further details on the side drive spiral conveyor please click on the below link:

https://www.youtube.com/watch?v=gfeQA9m_5ys

Conclusion: The Impact of Spiral Conveyors on Operational Efficiency

Spiral conveyors have continued to have an enormous impact on operational efficiency by enhancing the way systems are designed to handle various products and materials. Spiral conveyors are engineered to operate seamlessly with different types of product loads, thanks to their ability to incorporate features like rolling friction belts and two tracks.

The speed at which spirals can move products ensures a continuous flow, which significantly improves throughput. Optimizing the spirals design for operational needs, ensures greater efficiency and reliability in the material handling process.

Get In Touch With Jarlam: Your Experts for Spiral Conveyor Design & Fabrication

For more information about Jarlam and our expertise, please contact us on 03 9762 6833 or visit our website to learn about our experience and download our Capability Statements.